Selected Reprints

Borden's Condensed Milk Factory Site, Burr Pond State Park, Torrington CT, A New CT Archaeological Preserve

by Faline Schneiderman, RPA, Historical Perspectives, Inc.

Click on each maroon-bordered image to bring up a larger view.

The Friends of the Office of State Archaeology, Inc. (FOSA) led the way to have five sites located on lands

administered by the Department of Energy and Environmental Protection (DEEP) surveyed, studied and nominated to

the State Register of Historic Places (SR). Funded by grants from the Connecticut State Historic Preservation

Office (SHPO), one of these significant industrial archaeological sites, the Gail Borden Condensed Milk Factory

Site at what is now Burr Pond State Park, was nominated as an SR site and designated as a State Archaeological

Preserve in May. The factory site was Borden's first successful milk condensing operation, occupying a building

next to Burr Mountain Road between 1857 and ca. 1859/60. Built by Milo Burr in 1854, the structure burned down

in 1874.

The Gail Borden Condensed Milk Factory site in Burr Pond State Park in Torrington is significant for its

association with the entrepreneur and inventor, Gail Borden, Jr., who devised and patented a technique in 1856

for condensing liquids, most notably milk. The site is the first commercially successful condensed milk factory

in the United States.

![]()

![]()

The site contains the remains of a tri-level stone factory foundation, originally built by Burr and a

7.2-foot-wide, dry-laid split fieldstone enclosed wheel pit at its north end where there was once an overshot

wheel (photograph 1). There is currently a partially buried, rusted turbine in this location (photograph 2).

The site contains the remains of a tri-level stone factory foundation, originally built by Burr and a

7.2-foot-wide, dry-laid split fieldstone enclosed wheel pit at its north end where there was once an overshot

wheel (photograph 1). There is currently a partially buried, rusted turbine in this location (photograph 2).

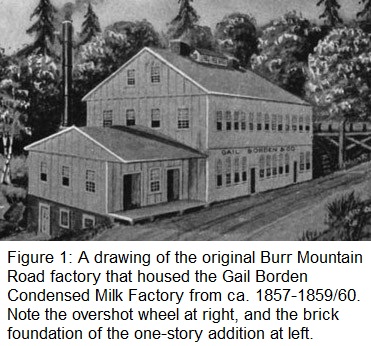

The foundation is approximately 63 feet long north to the south, paralleling Burr Mountain Road, and 40 feet in

width perpendicular to the road. Scattered brick on the surface and an 1855 drawing of the factory indicate that

a destroyed portion of the foundation was once located immediately south of the extant fieldstone (Figure 1).

A wooden State Park sign on the southwest side of Burr Mountain Road publicizes the location of the famous

factory site. In the 1950s, a boulder-mounted bronze plaque was placed to commemorate the site, but it has since

been removed. The boulder is all that remains.

Scattered on the surface in the vicinity of the foundation are historical artifacts including metal pipes,

unstamped bricks, architectural rubble, broken bottle glass, and a limited number of ceramic shards. In order to

confirm subsurface conditions for the purposes of this nomination, one Shovel Test excavation was conducted

about 10 feet south-west of the foundation (12/18/2014). Located between the foundation and the stream, testing

encountered a deep sandy clean level of fill from the surface down to 19 inches below surface (inbs), at which

point a pocket of brick fragments, glass, and whiteware was encountered. This level continued down to 27inbs,

where a second layer of sandy fill was encountered. This second level contained what appeared to be decomposing

fragments of wood planks to a depth of 29inbs. Beneath this was a third sandy level devoid of artifacts to a

depth of 35.5inbs.

The process Borden developed for condensing milk is considered a significant landmark in the history of the

dairy industry, and made canned milk a pantry staple. After receiving a patent for his condensing pan, Borden

made several attempts to produce condensed milk commercially, first in Wolcottville, elsewhere in Torrington.

When this proved unsuccessful, he established his factory in a building on what is now Burr Mountain Road in

1857.

Borden's first product was unsweetened condensed milk (with no added sugar) that was delivered to cities,

likely by rail, and served from forty quart cans on a pushcart at twenty five cents a quart. Two and a half

quarts of water added to one quart of condensed milk made three and a half quarts of cream. More water made five

quarts of rich milk or seven quarts of good milk. Although it was recognized that Borden's condensed milk was

superior to any evaporated or condensed milk previously attempted, the company could not boost sales, and could

not offset the cost of operating the factory in Burrville. Yielding to the monetary problems of that year, the

company suspended operations for part of 1857, leaving Borden liable for debt for which he was sued. The factory

reopened later that year.

His product ultimately proved to be a success. At one point, the Burrville factory was processing roughly

2000 gallons of milk per day. An 1859 article in the New Britain Times described the factory as follows:

The long and short of the process is that fresh milk is received night and morning, and condensed to one-fourth of its original bulk by evaporation.... To anyone entering Mr. Borden's buildings, the great cleanliness, the smell of fresh milk and clean tins, the white floors and general absence of everything in the least doubtful, as if everything from the floor-boards to the ceiling challenged inspection - is quite overpowering.... The milk is strained and put ...into ten gallon open-top cylinders; and after standing in a tank of ice-water till deprived of animal heat, it is heated up to 190 degrees, by setting these cylinders or heaters in a tank of water heated up to this point. A creamy scum rises, which is removed, and this is found to contain butter to the amount of one pound to 2000 quarts of milk. This unavoidable loss is the only deterioration which the milk suffers. A small portion of hard, indigestible viscid albumen attaches itself very firmly to the sides of the beaters. Freed from these, the milk is again strained, and at the temperature above stated, transferred to the condenser on the floor above. This is a globe of iron fitted with a steam jacket for the lower half and provided with a steam-pipe coiling several times about within....the condenser is capable of holding about 1000 to 1200 quarts. Connected with the condenser or "vacuum pans" is a barometer to show the degree of exhaustion, and a thermometer to mark the temperature, which is kept at about 150 degrees. The exhaustion is effected by an air pump, and the exhaust pipes pass through cold water to condense the steam rising from the milk. The air which, when the exhaustion first begins, is thrown off from the milk, is strange as it appears of an exceedingly disagreeable smell, a sort of cow or cow yard odor, which is so offensive that special pains have been taken to conduct it away from the house; this notwithstanding the great pains taken to have the milk clean and pure...

The venture gained the attention of a serious financial investor who partnered with Borden and financed the 1860 relocation of the factory to Winsted, and a second in Wassaic, New York near the train line to New York City. An 1862 flood from the burst dam at Burr Pond damaged much of the foundations of the original factory structure, but left sections intact. Despite this, the structure was repaired and in use by John M. Burr in 1874 as a Woolen Mill. On May 12, 1877, what remained of the building was consumed by fire. The stone portion of the foundation was left largely intact.