Selected Reprints

The Mighty Moodus River

by Jim Trocchi I remember the words of the late and multi-talented Don Malcarne, ASC Treasurer and a speaker at many

archaeological and historical events saying, "You don't have to dig to be an archaeologist." In essence he was

saying that a place such as New England has many abandoned historical features and sites that are exposed on the

surface and are waiting for the keen eye to further investigate and possibly reinterpret them. In Connecticut we

are fortunate to have many of these features in various stages of decay waiting to be explored. I am constantly

running into them as I drive and hike the woodlands of our state. So, for those who like to explore Connecticut's

many historical and archaeological features, one suggestion is visit the riparian banks of the Moodus River. It

is an interesting place where one can feed this appetite and in the early winter until spring, when the foliage

has fallen, sites and features are well exposed. The Moodus River is especially interesting to both those

interested in America's Industrial Revolution and in Industrial Archaeology.

The Moodus River once provided water power for 12 mills along its 3-mile, 300-foot descent to its confluence

with the Salmon River. These mills were established as early as 1819, the start of the American Industrial

Revolution, and many stayed in operation into the 20th century. The Moodus River begins its journey from the

lower Moodus Reservoir to the confluence of the Salmon River, all within the boundaries of East Haddam. Its

300-foot drop and the backing of a large watershed and available land on its banks made it an excellent location

for waterpower to propel industrial growth. "The Moodus River empties into the Salmon River at the Cove in

Johnsonville. Although it certainly is not a big river (it more closely approximates a stream. The word 'river'

is loosely applied in this case), the river bed declines approximately three hundred feet in three miles, and its

power was easily harnessed by dams and waterwheels The land adjoining the river was, at this time, unimproved,

and there were many available sites for mill development." (Sievers 2007:1). The remains of the dams, head races,

penstocks, turbines and building structures still remain for one to view today,

Further, as stated above, its location was close to the Connecticut River for all its transportation needs

to import and export goods. "In central Connecticut the Connecticut River was the passageway from local towns to

New York City and beyond. Moodus' location as a Connecticut River town meant that raw cotton from New York

wharves could be delivered on a regular schedule to Goodspeed Landing, and that the steamboats, on their return

voyages, could transport the finished goods from Moodus to selling agents in the City." (Sievers 2007:1). The

raw material that fed the mills was cotton imported from the South. The raw material was then carded and spun to

provide their main finished product of twine. Other products these mills were mainly known for were yarn and

duck. Duck is sailing cloth which was in high demand during the age of sailing ships (clippers). By a more

specific definition, duck is a cotton or linen cloth like canvas, but lighter in weight. "The Moodus cotton

mills concentrated primarily on manufacturing three different products: yarn, duck, and twine." (Sievers 2007:1).

"Twine, however, was the major product of Moodus involving, at one time or another, all twelve mills. The twine

was sold either as cord or made directly into fish nets." (Sievers 2007:1). Therefore, for all of the mills on

the Moodus River, the main product was cotton twine. It was probably the twine capital of America.

A good place to start your road trip to view what remains of these mills is at the beautiful dam at the

Lower Moodus Reservoir; the 300-foot elevation mentioned above. To see this location, at the intersection of

Connecticut's Route 149 and Route 16 in the Westchester section of Colchester, drive south on Route 149 for

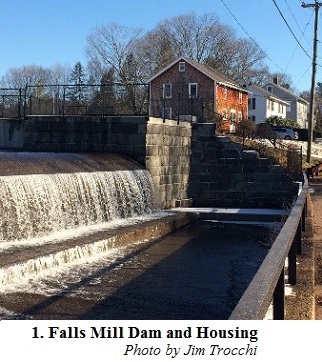

about two miles until you come to Falls Bashan Rd. on the left. Photo 1 shows what is left of the Falls Mill.

Though the mill itself has long since been destroyed, three houses remain that were occupied by mill workers.

A good place to start your road trip to view what remains of these mills is at the beautiful dam at the

Lower Moodus Reservoir; the 300-foot elevation mentioned above. To see this location, at the intersection of

Connecticut's Route 149 and Route 16 in the Westchester section of Colchester, drive south on Route 149 for

about two miles until you come to Falls Bashan Rd. on the left. Photo 1 shows what is left of the Falls Mill.

Though the mill itself has long since been destroyed, three houses remain that were occupied by mill workers.

"Practically all the mills had tenements, multi-family dwellings, which were rented for one to three dollars

a month to mill operatives. Some have been destroyed, but a fair number still remain as private, two-family

homes." (Siever 2007:2). Today these former tenements have been updated to single family owners and are in a

beautiful recreational area. There are some remains of the Falls Mill and one other mill but they can't be

observed because they are on private property.

From Falls Mill, continue further south on Route 149 less than a mile, just past some more mill tenements on

your left, to the Berstein Preserve, also on your left. Caution, the road curves here so be careful for oncoming

traffic. You will be driving into someone's shared driveway but not trespassing. "The preserve is accessed via

Land Trust property that serves as a driveway for the house on the east side of Route 149/Falls Road, about 100

feet south of Andrews Road. Park off the right of the driveway."

From Falls Mill, continue further south on Route 149 less than a mile, just past some more mill tenements on

your left, to the Berstein Preserve, also on your left. Caution, the road curves here so be careful for oncoming

traffic. You will be driving into someone's shared driveway but not trespassing. "The preserve is accessed via

Land Trust property that serves as a driveway for the house on the east side of Route 149/Falls Road, about 100

feet south of Andrews Road. Park off the right of the driveway." See the following website for more info.

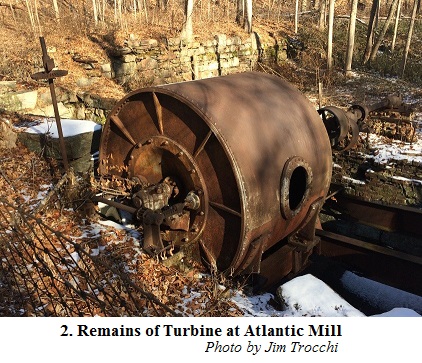

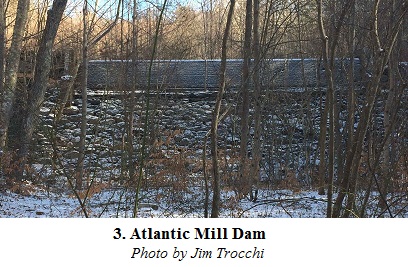

"As the decade of the 1930's was approaching a close, fire once again claimed the life of a Moodus mill. This time the Atlantic Mill fell victim to the flames. At the end of each workday electric blowers were used to clean the machines and floor of waste cotton. During this operation the air inside the mill was full of floating fibers of cotton. The fire was caused by exposed wires on an extension cord igniting some cotton on the floor. According to an eyewitness, Joe Wolak, a flash fire erupted because of the quantity of cotton dust in the air. Workers gave the alarm and evacuated the building, some jumping from second floor windows. Miraculously, no one was killed. The local fire department, volunteers, and boys from the nearby Civilian Conservation Corps camp all tried to bring the fire under control, but their efforts were unsuccessful. The mill was a total loss." (Sievers 2007:3). A 1934 aerial photo, in the Connecticut State Library Digital Collection, has a great view of the Mill building encompassing the turbine. Also, standing here and looking uphill from the turbine, you can see the penstock and head race that fed water to power the turbine. Also seen is the tenement housing at the very top, for the mill's opera-tives. These houses you passed before turning into the Preserve. They look of the same style seen at the Falls Mill. Walk further in on the preserves path and you will encounter a spectacular large dam, shown in Photo 3, that impounded the water supply for the Atlantic Mill.

A short distance to the left and up a small hill you'll see where the dam has been breached and across from it the start of the Mill's head race.

Heading south after leaving the Berstein Preserve, drive about a half mile into Moodus Center to Gristmill

Rd. on your right and follow it about a quarter of a mile to the Hidden Valley Preserve, also on your right.

Follow the preserve's map trail system to view the remains of two dams and a turbine. This is a pleasant one

mile walk on both sides of the Moodus River. As you enter the trail and stay to the right you will come across

the remains of a turbine, identical to the one at the Atlantic Mill, with its head and tail race feeding into it.

The path on the opposite side of the River takes you to the large dam that impounded the water that was released

into the head race and turbine seen earlier.

Heading south after leaving the Berstein Preserve, drive about a half mile into Moodus Center to Gristmill

Rd. on your right and follow it about a quarter of a mile to the Hidden Valley Preserve, also on your right.

Follow the preserve's map trail system to view the remains of two dams and a turbine. This is a pleasant one

mile walk on both sides of the Moodus River. As you enter the trail and stay to the right you will come across

the remains of a turbine, identical to the one at the Atlantic Mill, with its head and tail race feeding into it.

The path on the opposite side of the River takes you to the large dam that impounded the water that was released

into the head race and turbine seen earlier.

After leaving this site, heading back further south on Route 149 go to the next road on your right which is

North Moodus Rd. Follow it and take a quick left onto Red Mill Lane. Follow it down the hill a short distance

and park by a beautiful abandoned stone arch bridge that is an artifact in itself. This area is the back side of

the old Moodus downtown that was relocated during government subsidized urban renewal of the 60's and 70's. A

short distance downstream from the stone arch bridge, is a large concentration of remains of the busy twine

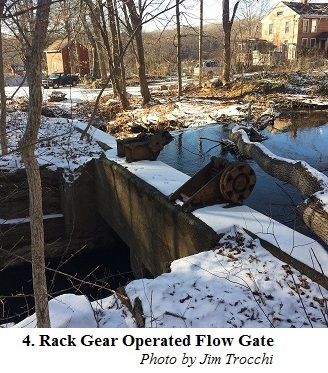

industry that once existed here. Photo 4 is a view from the top of an intact dam with its rack gear operated

gate to control the flow of water into the head race. Follow the head race just a little downstream and you'll

see another rack gear operated flow gate that controlled the flow of water to power the turbine.

After leaving this site, heading back further south on Route 149 go to the next road on your right which is

North Moodus Rd. Follow it and take a quick left onto Red Mill Lane. Follow it down the hill a short distance

and park by a beautiful abandoned stone arch bridge that is an artifact in itself. This area is the back side of

the old Moodus downtown that was relocated during government subsidized urban renewal of the 60's and 70's. A

short distance downstream from the stone arch bridge, is a large concentration of remains of the busy twine

industry that once existed here. Photo 4 is a view from the top of an intact dam with its rack gear operated

gate to control the flow of water into the head race. Follow the head race just a little downstream and you'll

see another rack gear operated flow gate that controlled the flow of water to power the turbine.

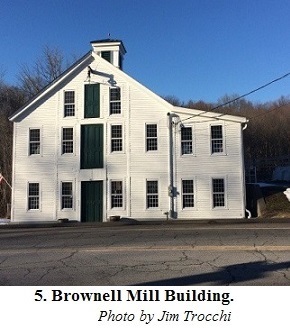

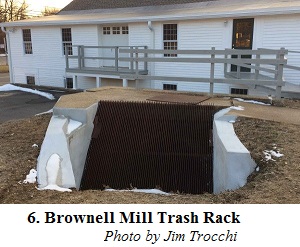

Downstream you come upon the area behind the Brownell Company, which stayed in business until 1977. "During the 1930's the DuPont Corporation had perfected a new synthetic called nylon which they hoped to market as an alternative product to cotton." (Sievers 2007:5). Most of the old cotton twine mills weren't willing to change over to nylon. "One mill, however, did refer DuPont representatives to the Brownell Company in Moodus where they were favorably received by Crary Brownell and his son Nathan. The Brownells realized that nylon was to become the fiber of the future; to accept or reject its inevitability could mean the difference between financial success or failure. The Brownells agreed to become the first twine mill to convert from the manufacture of cotton to nylon seine, and to introduce nylon twine to the commercial fishing market. In return, DuPont made Brownell the exclusive manufacturer of nylon seine twine for a period of five years. This would allow Brownell the opportunity to develop the product and to conduct market research. The success of the Brownell mill in manufacturing and selling nylon seine twine ensured the economic survival of the company. The Brownell Company has survived for 140 years as a result of hard work, manufacturing and product innovation, market diversification, and good luck." (Sievers 2007:5). One of the buildings from the Brownell Mill complex is shown in Photo 5. It has been nicely restored and can be viewed from Route 149 as you leave the center of Moodus. On the right hand side of this building is where the pen stock once entered the building but it has since been filled with concrete. Water fed through this pen stock powered the Mill's turbine. Further, Photo 6 shows the trash rack that prevented foreign objects from entering the pen stock and causing damage to the turbine. As you see, all these features have been nicely preserved in the renovation of this building.

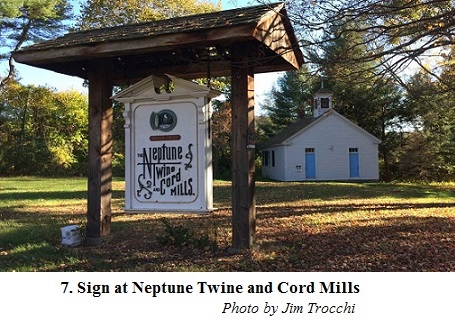

Finally, you can reach the last mill on the Moodus River by continuing south on Route 149 for about one mile until you come to Johnsonville Rd. on your right. Proceed down the road to this enchanting abandoned village. This is private property, so please don't trespass. As you head down Johnsonville Rd. and through the Village, you will first come upon a mill pond, dam and tail race on your right that powered the last mill on the Moodus River before its confluence with the Salmon River. In its former days it was home to Neptune Twine and Cord, whose sign shown in Photo 7 has been nicely preserved. This abandoned village was recreated in the 1970's and only a Victorian house is original. Nearly all of the historical buildings here are authentic but were moved here from other places. More can be found about it at:

The following very nicely sums up the stages of twine manufacture in Moodus. "There were three distinct

stages in the history of seine twine manufacturing, each characterized by the use of a different fiber in the

production process. Twine was first made from linen, a derivative of the flax plant. The transition to the

second stage of development was initiated by Ebenezer Nichols of Moodus who, in the early 1820's, conceived the

idea of substituting cotton for linen in the manufacturing of seine twine. With his invention of the Whirl-A-Gig

twister, the production of cotton seine twine began in Moodus. The fishermen soon came to realize that cotton

twine was a more economic product than linen, and Moodus' domination of the cotton seine industry was ensured

for many years. The third stage in the history of twine production was instituted by the Brownell Company when

they became the first seine twine mill in the nation to convert to the manufacture of nylon twine. Today,

practically all seine twine used for commercial fishing is made from synthetic fiber. Moodus, Connecticut, can

justifiably be nicknamed the 'Twine Capitol of America' for its leading role in initiating the development of

cotton and nylon seine twine." (Sievers 2007:5).

In conclusion, its experiences like these that can so enhance your life in the place you live. As I travel

around our rich and scenic region, I've learned to stop and explore. You never run out of places to seek out.

Now, when I take my next trip to see a show down at the Goodspeed Opera House and travel down Connecticut Route

149 through this area, it will have ever more meaning to me.

References:

Sievers, Bruce R. 2007. "The Cotton Mills of Moodus: How Moodus Became the 'Twine Capital of America'".

Simon Pure Productions,

Note: This website is no longer available. A similar book, also by Bruce R.

Sievers, titled, "Mills Along the River: The History of The Cotton Industry in Moodus, Connecticut" is suggested

as an alternate source.